Brake pumps, commonly referred to as master cylinders, are essential components in a vehicle’s hydraulic braking system. They play a crucial role in converting the force applied to the brake pedal into hydraulic pressure, which is then transmitted to the brake calipers or drums to stop the vehicle. In this article, we’ll explore how brake pumps (master cylinders) work, their function in braking systems, and the importance of maintaining them for safe and efficient braking.

1. What is a Brake Pump (Master Cylinder)?

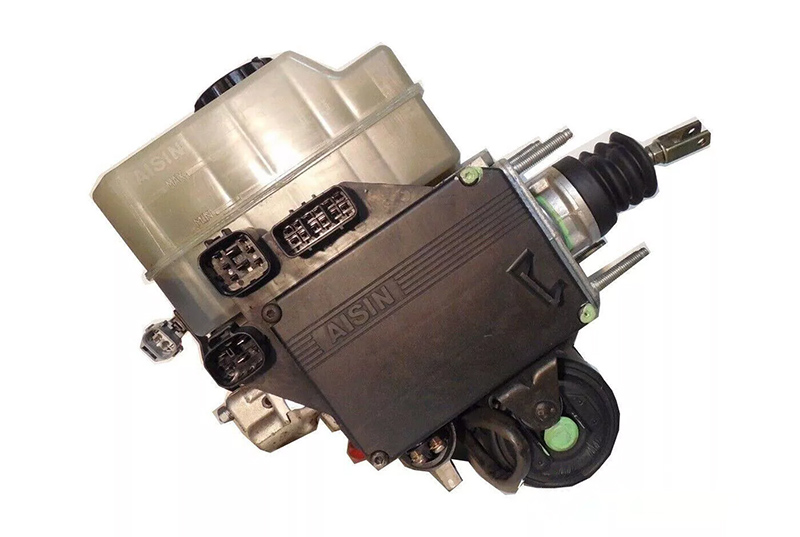

The brake pump, also known as the master cylinder, is a hydraulic pump that controls the flow of brake fluid to the rest of the braking system. It sits between the brake pedal and the brake lines, managing the pressure of the brake fluid that activates the brakes. When you press the brake pedal, the master cylinder pushes brake fluid through the brake lines to the calipers or wheel cylinders, which then apply pressure to the brake pads or shoes, bringing the vehicle to a stop.

2. How a Brake Pump (Master Cylinder) Works

The brake pump operates as part of a hydraulic braking system, which uses incompressible brake fluid to transfer force from the brake pedal to the brakes. Here’s a step-by-step breakdown of how it works:

- Brake Pedal Depressed: When the driver presses the brake pedal, it applies force to a piston inside the master cylinder. This force is transmitted mechanically from the pedal to the cylinder through a pushrod.

- Hydraulic Pressure Created: The master cylinder contains brake fluid in a reservoir. As the piston moves forward inside the cylinder, it pushes brake fluid into the brake lines, creating hydraulic pressure. The fluid moves through the brake lines to the brake calipers or wheel cylinders.

- Brakes Engaged: The hydraulic pressure from the brake fluid forces the brake calipers (in disc brake systems) or wheel cylinders (in drum brake systems) to engage the brake pads or shoes against the rotors or drums. This friction slows down or stops the vehicle.

- Brake Pedal Released: When the driver releases the brake pedal, the piston inside the master cylinder retracts, reducing the hydraulic pressure in the brake lines. The brake pads or shoes disengage from the rotors or drums, allowing the vehicle to move freely again.

3. Types of Master Cylinders

There are two main types of master cylinders used in vehicles:

- Single-Circuit Master Cylinder: Found in older vehicles, this type of master cylinder has a single hydraulic circuit, meaning that one line supplies pressure to all four brakes. If the system fails, the entire braking system can be compromised, which is why it is no longer commonly used.

- Dual-Circuit Master Cylinder: Most modern vehicles use dual-circuit master cylinders, which divide the hydraulic pressure between two separate circuits (typically front and rear). This design provides a backup in case one circuit fails, ensuring that the vehicle still has partial braking capability.

4. Components of a Master Cylinder

A typical master cylinder consists of several key components that work together to create and control hydraulic pressure:

- Piston: The piston is the internal component that moves forward when the brake pedal is pressed, generating hydraulic pressure by displacing the brake fluid.

- Brake Fluid Reservoir: This is where brake fluid is stored. The reservoir supplies fluid to the master cylinder as needed and is essential for maintaining the hydraulic pressure in the system.

- Pushrod: The pushrod connects the brake pedal to the master cylinder piston. When the driver presses the brake pedal, the pushrod pushes the piston forward inside the master cylinder.

- Seals and O-rings: These components ensure that brake fluid is contained within the master cylinder and brake lines, preventing leaks and maintaining pressure.

5. Integration of Master Cylinders with ABS Systems

In modern vehicles, anti-lock braking systems (ABS) work in conjunction with the master cylinder to enhance braking performance and safety. ABS is designed to prevent the wheels from locking up during hard braking or on slippery surfaces, allowing the driver to maintain control of the vehicle.

When the driver applies the brakes, the master cylinder creates hydraulic pressure as usual. However, if the ABS system detects that one or more wheels are locking up, it temporarily reduces the hydraulic pressure to those wheels by modulating the brake fluid flow. This process is done through the ABS control module and solenoid valves, which rapidly pulse the brakes, allowing the tires to regain traction. The master cylinder works in harmony with the ABS to maintain brake fluid flow and ensure that pressure is regulated without manual intervention from the driver.

The integration of the master cylinder with ABS ensures a balance between traditional hydraulic braking and advanced electronic control. Together, they provide greater braking precision, especially in emergency situations or adverse road conditions.

6. Common Issues with Brake Pumps (Master Cylinders)

While master cylinders are designed to be durable, they can experience wear and tear over time, leading to braking issues. Common problems include:

- Brake Fluid Leaks: If the seals in the master cylinder wear out or become damaged, brake fluid can leak, reducing hydraulic pressure and affecting the performance of the brakes.

- Spongy Brake Pedal: A spongy or soft brake pedal is often a sign of air trapped in the brake lines. This can happen if the master cylinder is not properly sealed or if there is a brake fluid leak.

- Brake Fluid Contamination: Dirt, moisture, or other contaminants in the brake fluid can affect the performance of the master cylinder, leading to poor braking performance.

- Brake Pedal Sinking: If the brake pedal sinks slowly to the floor when pressed, it may indicate that the internal seals in the master cylinder are worn or damaged, allowing brake fluid to bypass the piston rather than creating pressure.

7. Maintenance and Care for Brake Pumps (Master Cylinders)

Proper maintenance of the brake pump (master cylinder) is crucial for the safety and performance of your vehicle’s braking system. Here are some tips to ensure your master cylinder remains in good working order:

- Regularly Check Brake Fluid Levels: The brake fluid reservoir should be checked regularly to ensure it has the correct amount of fluid. If the fluid level is low, it could indicate a leak in the system.

- Replace Brake Fluid: Over time, brake fluid can absorb moisture, which can lead to corrosion in the braking system and reduce the effectiveness of the master cylinder. Regularly replacing the brake fluid (as per the vehicle manufacturer’s recommendations) helps maintain the system’s efficiency.

- Inspect for Leaks: Check the area around the master cylinder and the brake lines for any signs of fluid leaks. If you notice fluid leaking, have the master cylinder inspected and repaired immediately.

- Bleed the Brake Lines: If air gets into the brake lines, it can reduce hydraulic pressure and cause a spongy brake pedal. Bleeding the brake lines removes air from the system, ensuring that the master cylinder operates effectively.

8. Conclusion

The brake pump (master cylinder) is an essential part of a vehicle’s hydraulic braking system, ensuring that hydraulic pressure is transmitted to the brakes when the pedal is pressed. It also works closely with modern ABS systems to provide enhanced safety and control, preventing wheel lockup in emergency braking situations. Proper maintenance, including checking brake fluid levels, bleeding the brakes, and inspecting for leaks, is crucial for safe and efficient braking. Understanding how your vehicle’s master cylinder works and how to maintain it can help prevent brake failure and keep you safe on the road.