The pump technology landscape is experiencing a remarkable transformation in 2025, with breakthrough innovations reshaping both automotive applications and industrial equipment. From enhanced efficiency to unprecedented levels of intelligent control, these advances are setting new standards for performance and sustainability.

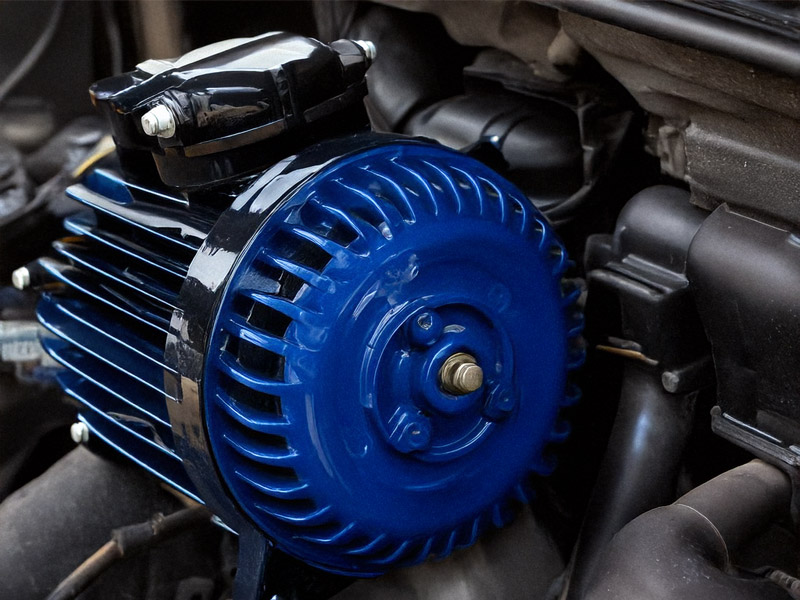

Electric Vehicle Cooling Systems: The Next Generation

The rapid evolution of electric vehicles has catalyzed significant developments in cooling pump technology. Modern EVs require sophisticated thermal management systems to maintain optimal battery temperatures and maximize range. The latest innovations include:

Variable-Flow Smart Pumps

Advanced variable-flow pumps with integrated AI controllers can now dynamically adjust coolant flow rates based on real-time temperature data and driving conditions. These systems reduce energy consumption by up to 30% compared to traditional fixed-flow pumps, directly contributing to extended vehicle range.

Multi-Circuit Integration

New modular pump designs incorporate multiple cooling circuits within a single unit, managing battery, power electronics, and cabin climate control simultaneously. This integration reduces system complexity, weight, and manufacturing costs while improving overall thermal efficiency.

Industrial Applications: Precision and Efficiency

The industrial sector has seen equally impressive advances in pump technology, particularly in high-precision manufacturing and process control applications.

Digital Twin Technology

Modern industrial pumps now incorporate digital twin capability, enabling real-time monitoring and predictive maintenance. These systems create virtual replicas of physical pumps, allowing operators to:

- Monitor performance metrics in real-time

- Predict maintenance needs before failures occur

- Optimize operating parameters for maximum efficiency

- Simulate different operating conditions without risk

Energy-Harvesting Pumps

A groundbreaking development in 2025 is the introduction of energy-harvesting pump systems. These innovative designs capture waste energy from fluid flow and vibration, converting it into usable electricity to power sensors and control systems. This technology reduces the need for external power sources and supports the growing trend toward autonomous industrial systems.

Sustainability-Focused Innovations

Environmental considerations continue to drive pump technology development, with several noteworthy advances:

Bio-Inspired Materials

New biomimetic materials used in pump components offer superior wear resistance and reduced friction, leading to longer service life and lower energy consumption. These materials, inspired by natural structures, also eliminate the need for harmful lubricants in many applications.

Water Conservation Technology

Smart irrigation pumps with integrated moisture sensors and weather prediction capabilities can reduce water usage by up to 40% while maintaining optimal soil conditions. These systems are particularly valuable in agricultural applications and large-scale landscaping.

Integration with IoT and Industry 4.0

The latest pump technologies seamlessly integrate with broader Industrial Internet of Things (IIoT) networks, offering unprecedented levels of control and monitoring:

Cloud-Connected Systems

Modern pumps feature built-in connectivity that enables:

- Remote monitoring and control through secure cloud platforms

- Integration with facility-wide management systems

- Automated performance optimization based on machine learning algorithms

- Real-time data analytics for efficiency improvements

Augmented Reality Integration

Maintenance and operation of complex pump systems is simplified through augmented reality interfaces. Technicians can access real-time performance data, maintenance histories, and step-by-step repair guides through AR displays, reducing downtime and improving service quality.

Future Outlook

As we move through 2025, several emerging trends suggest the future direction of pump technology:

Quantum Sensors

Development is underway on quantum sensors for ultra-precise flow measurement and control, potentially revolutionizing high-precision manufacturing and chemical processing applications.

Self-Healing Materials

Research continues into self-healing materials for pump components, which could dramatically extend service life and reduce maintenance requirements.

Conclusion

The innovations in pump technology for 2025 represent a significant leap forward in efficiency, intelligence, and sustainability. As these technologies mature and new developments emerge, we can expect to see continued improvements in performance, reliability, and environmental impact across both vehicular and industrial applications.