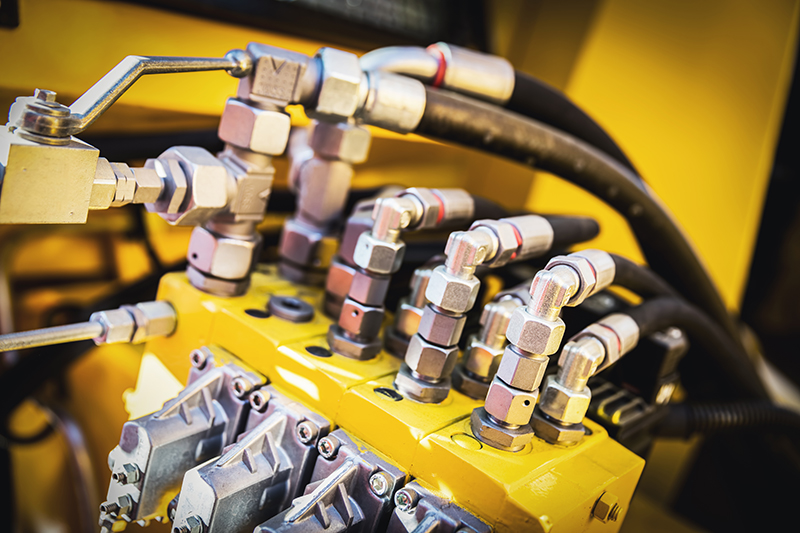

The industrial vehicle pump market represents a critical segment of the global fluid power industry, serving diverse applications from construction and mining equipment to agricultural machinery and commercial transportation. These specialized pumps must withstand extreme operating conditions while delivering precise performance, reliability, and efficiency that directly impact vehicle productivity and operational costs. Industrial vehicles operate in some of the world’s harshest environments, from dusty construction sites and muddy agricultural fields to scorching desert mining operations and freezing winter conditions. The pumps that power these machines must therefore combine robust mechanical construction with sophisticated hydraulic engineering to ensure consistent performance across temperature extremes, varying load conditions, and demanding duty cycles.

The evolution of industrial vehicle pumps has been driven by increasing demands for fuel efficiency, environmental compliance, and operational productivity. Modern industrial vehicles require pumps that can deliver precise flow control, rapid response times, and seamless integration with electronic control systems. The trend toward electrification and hybrid powertrains has further accelerated innovation in pump technology, with manufacturers developing solutions that can operate efficiently across various voltage levels while maintaining the durability and performance characteristics required for industrial applications. Additionally, the growing emphasis on total cost of ownership has pushed pump manufacturers to focus not just on initial performance, but on long-term reliability, serviceability, and lifecycle efficiency.

Quality and reliability in industrial vehicle pumps are paramount, as equipment downtime in these applications can result in significant financial losses. A single excavator breakdown can halt an entire construction project, while agricultural equipment failure during harvest season can cause irreparable crop losses. This reality has driven the industry toward partnerships with established manufacturers who possess the engineering expertise, manufacturing capabilities, and global support networks necessary to ensure continuous operation. The leading pump manufacturers in this space have invested heavily in research and development, advanced manufacturing technologies, and comprehensive testing programs to deliver products that meet the exacting standards of industrial vehicle OEMs and end users alike.

Here are the leading manufacturers of industrial pumps for vehicle applications:

1. Bosch

Bosch stands as a global leader in automotive and industrial pump technology, leveraging over a century of engineering expertise to deliver precision-engineered solutions for demanding vehicle applications. The company’s comprehensive pump portfolio includes high-pressure fuel injection pumps that have revolutionized diesel engine efficiency, robust hydraulic pumps for construction and agricultural equipment, and advanced cooling system pumps for heavy-duty applications. Bosch’s commitment to innovation is evident in their development of common rail fuel systems, electronically controlled pumps, and smart hydraulic solutions that optimize performance while reducing emissions. Their global manufacturing footprint and extensive service network ensure reliable support for industrial vehicle operators worldwide, while their investment in electrification technologies positions them at the forefront of the industry’s transition toward sustainable mobility solutions.

Specialties: Fuel injection pumps, hydraulic pumps, water pumps

Key Applications: Construction equipment, agricultural machinery, commercial vehicles

Notable Features: Advanced fuel injection technology, precision manufacturing, global service network

2. Eaton

Eaton has established itself as a premier supplier of hydraulic and fluid power solutions for mobile industrial equipment, with a particular strength in heavy-duty vehicle applications. The company’s hydraulic pump division produces a comprehensive range of gear pumps, vane pumps, and piston pumps designed to withstand the rigorous demands of construction, mining, and agricultural equipment. Eaton’s variable displacement pumps are renowned for their ability to match pump output to system demand, delivering significant fuel savings and improved operational efficiency. Their power steering pumps and transmission pumps incorporate advanced materials and precision manufacturing to ensure reliable operation under extreme conditions. Eaton’s focus on integrated system solutions, combined with their expertise in electronic controls and filtration, enables them to provide complete fluid power packages that optimize vehicle performance while minimizing maintenance requirements.

Specialties: Hydraulic pumps, power steering pumps, transmission pumps

Key Applications: Heavy-duty trucks, off-highway equipment, industrial vehicles

Notable Features: Variable displacement pumps, energy-efficient designs, robust construction

3. Parker Hannifin

Parker Hannifin represents the pinnacle of hydraulic pump technology for mobile applications, with an unmatched breadth of products serving virtually every industrial vehicle segment. The company’s mobile pump division specializes in compact, high-performance solutions that maximize power density while minimizing installation space and weight. Their gear pumps are particularly valued in construction and agricultural equipment for their simplicity and reliability, while their advanced piston pumps deliver the high pressure and precise control required for sophisticated hydraulic systems. Parker’s innovative approach to pump design includes features like integrated load sensing, pressure compensation, and electronic displacement control that enable intelligent hydraulic systems. Their global engineering capabilities and local manufacturing presence ensure that customers receive pumps optimized for specific regional requirements and applications, supported by comprehensive training and technical support programs.

Specialties: Hydraulic gear pumps, piston pumps, mobile hydraulics

Key Applications: Construction machinery, agricultural equipment, material handling vehicles

Notable Features: Compact designs, high pressure capability, extensive product range

4. Danfoss (Sauer-Danfoss)

Danfoss, which acquired Sauer-Danfoss’s mobile hydraulics business, has emerged as a technology leader in mobile hydraulics, with a particular focus on developing intelligent pump solutions that enhance vehicle productivity while reducing environmental impact. The company’s mobile pump portfolio encompasses everything from simple gear pumps for basic applications to sophisticated variable displacement pumps with integrated electronics for advanced machine control. Danfoss Sauer pioneered load-sensing hydraulic technology, which automatically adjusts pump output to match system demand, resulting in significant fuel savings and reduced heat generation. Their digital displacement technology represents a breakthrough in hydraulic efficiency, using electronically controlled valves to optimize pump performance in real-time. Danfoss Sauer’s commitment to sustainability is evident in their development of electro-hydraulic solutions and their focus on helping customers achieve carbon-neutral operations through improved system efficiency and reduced energy consumption.

Specialties: Mobile hydraulic pumps, transmission pumps, cooling system pumps

Key Applications: Agricultural tractors, construction equipment, forestry machinery

Notable Features: Load-sensing technology, fuel efficiency focus, intelligent pump systems

5. Continental (formerly VDO)

Continental brings automotive-grade precision and reliability to industrial vehicle pump applications, leveraging their extensive experience as an original equipment manufacturer to deliver solutions that meet the most demanding performance and durability requirements. The company’s pump portfolio focuses heavily on engine support systems, including electric water pumps that provide precise thermal management, fuel supply pumps designed for alternative fuels, and auxiliary pumps for specialized vehicle functions. Continental’s strength lies in their systems integration approach, developing pump solutions that work seamlessly with electronic control units, sensors, and other vehicle components. Their investment in electric pump technology positions them well for the industry’s shift toward electrification, with products that can operate efficiently across various voltage levels and provide the precise control required for modern powertrain applications. Continental’s automotive heritage ensures that their industrial vehicle pumps benefit from rigorous testing standards and quality processes developed for high-volume automotive production.

Specialties: Engine cooling pumps, fuel pumps, auxiliary pumps

Key Applications: Commercial vehicles, buses, specialty industrial vehicles

Notable Features: Electric pump technology, thermal management systems, OEM partnerships