The evolution of power steering systems represents one of the most dramatic transformations in automotive technology, fundamentally changing how drivers interact with their vehicles while dramatically improving fuel efficiency and system reliability. From the early days of purely mechanical steering that required substantial physical effort to today’s sophisticated electric assist systems that adapt to driving conditions in real-time, power steering technology has continuously evolved to meet changing demands for comfort, efficiency, and performance.

The journey began in the 1950s when automotive manufacturers first introduced hydraulic power steering to reduce the physical effort required to turn the steering wheel, particularly in heavy vehicles and during low-speed maneuvering. These early systems established the foundation for power steering technology that would dominate the automotive industry for over half a century before giving way to more advanced electric alternatives that offer superior efficiency and integration capabilities.

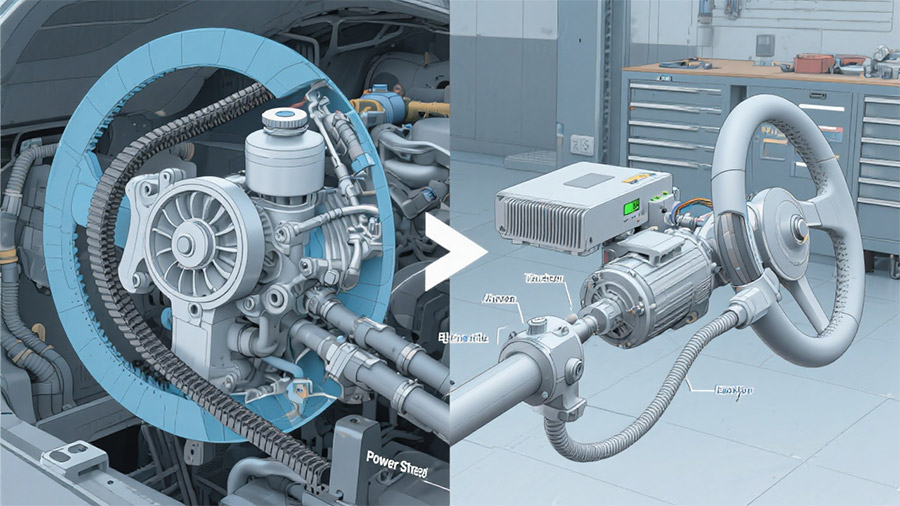

The Era of Belt-Driven Hydraulic Systems

Belt-driven hydraulic power steering pumps became the industry standard due to their ability to provide substantial assist force while maintaining direct mechanical connection between the steering wheel and road wheels. These systems utilized engine-driven pumps that pressurized hydraulic fluid to assist steering efforts through a power steering gear or rack-and-pinion assembly. The constant pressure system ensured immediate response to steering inputs while providing the substantial force multiplication necessary for effortless operation of heavy vehicles.

The mechanical simplicity of belt-driven systems contributed to their widespread adoption and long service life. Engine power transmitted through belt drives operated centrifugal pumps that maintained system pressure regardless of engine speed, though pressure output varied with RPM. Hydraulic assist levels remained relatively constant once minimum engine speeds were achieved, providing predictable steering feel that drivers could learn and trust. The direct mechanical connection ensured that steering control remained available even if the hydraulic assist failed completely.

However, belt-driven systems suffered from inherent inefficiencies that became problematic as fuel economy requirements tightened. The pumps operated continuously whenever the engine ran, consuming power even when steering assist wasn’t needed. This constant parasitic load reduced fuel economy by approximately 0.2-0.4 MPG in typical passenger cars, representing a significant penalty as efficiency standards became more stringent. Additionally, the mechanical drive systems required regular maintenance including belt replacement, fluid changes, and pump servicing that added to ownership costs.

Variable Assist and Electronic Integration

The introduction of variable assist systems marked the first major evolution beyond basic hydraulic power steering. These systems modified assist levels based on vehicle speed, providing maximum assistance during parking maneuvers while reducing assist at highway speeds to improve steering feel and stability. Early implementations used mechanical speed-sensing valves, while later systems incorporated electronic controls that enabled more sophisticated assist curves and integration with other vehicle systems.

Electronic integration enabled power steering systems to communicate with stability control, traction management, and driver assistance systems. This integration allowed steering assist to be modified based on driving conditions, vehicle dynamics, and even driver behavior patterns. Advanced systems could adjust assist levels during emergency maneuvers, provide steering input during stability interventions, or modify steering feel to enhance driver engagement during sporting applications.

The development of electronically controlled hydraulic systems provided a stepping stone toward full electric assist while maintaining the power capabilities of hydraulic systems. These hybrid approaches combined electric pumps with hydraulic assist mechanisms, eliminating the parasitic load of belt-driven pumps while maintaining the force multiplication advantages of hydraulic systems. Electronic pump control enabled on-demand operation that reduced energy consumption significantly compared to continuous-operation belt-driven systems.

The Electric Revolution

Electric power steering systems represent a fundamental paradigm shift that eliminates hydraulic components entirely while providing superior efficiency and integration capabilities. These systems use electric motors to provide steering assist directly through the steering column, pinion gear, or rack assembly. The elimination of hydraulic components reduces system complexity, eliminates maintenance requirements associated with fluid changes, and provides instant response to control inputs without the lag associated with hydraulic system pressure buildup.

The efficiency advantages of electric systems are substantial, with energy consumption occurring only when steering assist is actually needed. Modern electric power steering systems consume power only during steering inputs, reducing parasitic losses by up to 90% compared to traditional hydraulic systems. This efficiency improvement translates directly to improved fuel economy, with typical gains of 0.5-1.0 MPG depending on vehicle size and driving patterns.

Advanced electric systems provide capabilities impossible with hydraulic technology, including infinitely variable assist levels, active return-to-center forces, and integration with autonomous driving systems. The precise control available with electric motors enables features like lane-keeping assist, parking assistance, and emergency steering interventions that require precise force control and rapid response times. Modern systems can even provide tactile feedback through the steering wheel to communicate road conditions or system status to drivers.

Integration with Advanced Driver Assistance

The evolution toward electric power steering has enabled integration with advanced driver assistance systems that would be impossible with traditional hydraulic technology. Electric systems can provide steering inputs for lane-keeping assistance, automatic parking, and even emergency collision avoidance without any driver input. The precise control and rapid response capabilities of electric motors enable these systems to intervene smoothly and safely when necessary.

Autonomous vehicle development has further accelerated electric power steering evolution, as self-driving systems require complete control over steering functions. Electric systems provide the precise control, reliability, and integration capabilities necessary for autonomous operation while maintaining the ability to return control to human drivers instantly when required. The diagnostic and monitoring capabilities of electric systems enable continuous health monitoring that ensures system availability for safety-critical autonomous functions.

Future Developments and Emerging Technologies

Steer-by-wire technology represents the next evolution in power steering systems, completely eliminating mechanical connections between the steering wheel and road wheels. These systems use electric motors and electronic controls to translate steering wheel inputs into road wheel movements while providing artificial feedback to simulate traditional steering feel. Steer-by-wire systems enable unprecedented flexibility in vehicle design while providing safety advantages through redundant control systems and the ability to continue operation even if individual components fail.

The integration of artificial intelligence and machine learning enables power steering systems that adapt to individual driver preferences and driving conditions automatically. These intelligent systems can learn driver behavior patterns and adjust assist characteristics to match personal preferences while optimizing safety and efficiency. Future systems may incorporate predictive capabilities that anticipate steering needs based on road conditions, traffic patterns, and driver intentions.

The transformation from belt-driven hydraulic systems to sophisticated electric assist technology illustrates the rapid pace of automotive innovation driven by efficiency requirements, safety advancement, and the emergence of autonomous driving capabilities. This evolution continues as steering systems become increasingly integrated with vehicle networks and artificial intelligence systems that promise even greater improvements in safety, efficiency, and driver experience.