Heavy-duty engines operate in demanding environments that push lubrication systems far beyond the requirements of passenger car applications. These powerplants, found in long-haul trucks, construction equipment, marine vessels, and industrial generators, must deliver reliable performance under continuous high-load conditions, extreme temperatures, and extended operating intervals. The oil pump serves as the heart of these critical lubrication systems, ensuring adequate oil pressure and flow delivery to protect engine components worth hundreds of thousands of dollars while maintaining operational reliability that entire industries depend upon.

The consequences of lubrication failure in heavy-duty applications extend far beyond simple component replacement costs. A single engine failure can strand a commercial truck carrying time-sensitive cargo, shut down construction projects, or disable critical infrastructure equipment. Understanding the unique challenges faced by heavy-duty oil pumps and implementing appropriate maintenance strategies becomes essential for operators seeking to maximize equipment reliability while controlling lifecycle costs in demanding commercial applications.

Extreme Operating Environment Challenges

Heavy-duty engines operate under conditions that would quickly destroy conventional automotive engines. Continuous operation at high power outputs creates sustained high temperatures that stress oil pump components and the lubricants they circulate. Construction and mining equipment operates in dusty, contaminated environments where airborne particles inevitably find their way into lubrication systems despite advanced filtration. Marine applications expose engines to corrosive salt environments and constant vibration that accelerates component wear.

Temperature extremes present particular challenges for oil pump design and operation. Engine oil temperatures in heavy-duty applications routinely exceed 250°F, with some applications experiencing oil temperatures approaching 300°F during peak load conditions. These elevated temperatures reduce oil viscosity dramatically, requiring pumps to maintain adequate pressure despite thinner lubricants. Cold startup conditions present opposite challenges, as heavy-duty engines often use high-viscosity oils that create substantial pumping loads during initial operation.

Load cycling in heavy-duty applications differs fundamentally from passenger car duty cycles. While automotive engines experience frequent starts and stops with varying load conditions, heavy-duty engines often operate at sustained high loads for extended periods. This continuous high-power operation maintains elevated oil temperatures and pressures that stress pump components continuously. The extended operating intervals common in commercial applications mean that oil pumps must maintain performance for thousands of hours between major maintenance intervals.

Advanced Pump Technologies for Heavy-Duty Applications

Heavy-duty oil pumps employ robust construction techniques and materials specifically selected for extreme service conditions. Cast iron and steel construction replaces the aluminum components common in automotive applications, providing enhanced durability and heat resistance necessary for sustained high-temperature operation. Gear-type pumps dominate heavy-duty applications due to their positive displacement characteristics and ability to maintain pressure across wide viscosity ranges encountered during temperature cycling.

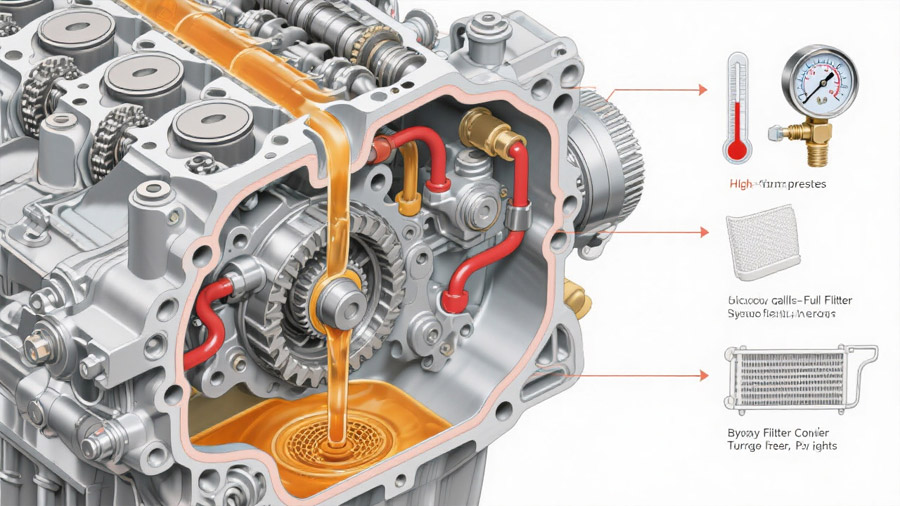

Variable displacement pumps have emerged as advanced solutions that optimize oil flow based on engine operating conditions. These systems reduce pumping losses during light-load operation while ensuring adequate pressure availability during peak demand conditions. Electronic controls monitor oil pressure, temperature, and engine load to adjust pump displacement continuously, optimizing energy consumption while maintaining adequate lubrication protection. Some systems incorporate pressure-relief bypass circuits that prevent excessive pressure buildup during cold operation with high-viscosity oils.

Multiple-stage pumping systems address the complex lubrication requirements of modern heavy-duty engines. Primary pumps supply main bearing circuits and cylinder head lubrication, while auxiliary pumps serve specialized functions like turbocharger lubrication, valve train actuation, or cooling system operation. This approach enables optimization of each circuit for specific requirements while providing redundancy that ensures continued operation if individual pump sections experience problems.

Filtration Integration and Contamination Management

Heavy-duty oil pumps operate within comprehensive filtration systems designed to protect against the contamination inherent in demanding operating environments. High-capacity full-flow filters remove particles that could damage pump internals or engine bearings, while bypass filtration systems provide continuous oil cleaning that extends service intervals. Centrifugal separators remove fine contamination and water that conventional filters cannot capture effectively.

Pump design considerations include contamination tolerance features that enable continued operation despite inevitable contamination ingress. Generous clearances between moving parts accommodate particulate contamination without binding, while hardened surfaces resist wear from abrasive particles. Internal bypass systems ensure oil flow continuation even if contamination partially blocks pump passages or if extreme viscosity conditions exceed normal pumping capacity.

Water contamination management becomes critical in marine applications and equipment operating in humid conditions. Oil pumps must handle occasional water ingress without sustaining damage, while water separation systems remove moisture before it can cause corrosion or lubrication degradation. Some heavy-duty systems incorporate heating elements that drive off moisture contamination during normal operation.

Maintenance Strategies and Monitoring Systems

Heavy-duty oil pump maintenance requires comprehensive strategies that address both scheduled maintenance and condition monitoring. Oil analysis programs track wear metals, contamination levels, and oil condition to optimize service intervals and detect developing problems before they cause failures. Pressure monitoring systems provide continuous assessment of pump performance, with alarm systems alerting operators to developing problems that require immediate attention.

Preventive maintenance programs for heavy-duty applications emphasize filter replacement, oil quality management, and systematic inspection of pump drive components. Extended service intervals common in commercial applications require high-quality oils and comprehensive monitoring to ensure adequate protection throughout service periods. Some operations implement oil conditioning systems that extend oil life through continuous cleaning and additive replenishment.

Advanced monitoring systems incorporate sensors that track oil pressure, temperature, and flow rates continuously. These systems can detect pump wear, contamination buildup, or developing restrictions before they affect engine protection. Predictive maintenance programs use this monitoring data to schedule maintenance based on actual component condition rather than fixed intervals, optimizing both protection and operational efficiency.

Performance Optimization and Future Technologies

Modern heavy-duty oil pumps incorporate design features that optimize performance while reducing parasitic losses. Variable-speed drives adjust pump operation based on actual lubrication requirements, reducing energy consumption during light-load operation while ensuring adequate capacity during peak demand. Electronic controls coordinate pump operation with engine management systems to optimize overall efficiency while maintaining protection.

Emerging technologies include smart pumps with integrated diagnostics that monitor their own condition and performance. These systems can detect wear, contamination, or developing problems automatically while providing predictive maintenance recommendations. Integration with telematics systems enables remote monitoring and analysis that optimizes maintenance scheduling and prevents unexpected failures.

The future of heavy-duty oil pump technology focuses on enhanced efficiency, intelligent monitoring, and integration with comprehensive engine management systems. As emissions regulations drive toward more efficient engines and extended service intervals, oil pump technology continues evolving to meet these demanding requirements while maintaining the reliability that commercial operations depend upon. Success in these applications requires understanding the unique challenges of heavy-duty operation and implementing comprehensive strategies that address both immediate performance requirements and long-term reliability objectives.